Aircraft Cowling - For Weick, the advantages of using such a proven method, although intuitive clear and logical, were a rather recent revelation. While at Buer in 1924 he learned, from propeller work carried out by William F. Durand and Everett

P. Lesley at Stanford University, what he called "the advantages of using a systematic series of independent variables in experimental research."22 (Even earlier, as a senior engineering student at the University of Illinois, he had based a paper on variable-pitch propellers on data from the Durand-Lesley

Aircraft Cowling

propeller tests in the Stanford wind tunnel.)23 So it was a method that had proven immensely practical to him in his own work, which gave him confidence to try it again. The amount of work is, in my estimation, the same for either process.

The female mold method, however, is a far more expensive process. There is little merit in making a female mold unless you intend to sell it or make extra cowlings from it. Anyway, no matter which method you favor, you will still have to make that basic male mold first.

There is one useful precaution to observe. Try not to get any of the glue dabs close to the surface that has to be further trimmed and sanded. Cured adhesive lumps are hard and cannot be filed or sanded smoothly without causing pockets of foam to tear out.

Actually, all you need are 3 or 4 small dabs of glue spotted away from the surface edges of each piece of foam. Applying a lot of glue is not wise. The less applied the easier your finishing job will be and the fewer repairs you will have to make.

The final treatment includes several coats of paint or varnish. Almost any kind will do. I took this opportunity to use up all the many leftover cans of spray paint that accumulated over the years. After the paint dries, sand the entire mold with 320 wet/dry paper to remove all the tiny bumps and dust particles.

Blow the mold clean and it is ready to receive the fiberglass lay-up. Because Tichenor did not understand the many advantages of engineering science, he dismissed the NACA cowling work as cut-and-try development. With the actual invention of the cowling, the editor charged, "the N.A.C.A.

had nothing whatever to do." Nevertheless, according to Tichenor, the NACA was claiming that, "had it not been for the NACA," the industry would not be adopting it. He wrote: Incidentally, some builders think it is necessary to allow for the settling of the engine somewhat in its shock mounts.

They deliberately mismatch the spinner-to-cowling fit in anticipation that the spinner, in time, will "sag" by about 1/8". It may never happen. If your engine has been installed for a number of months during construction, it

it is quite probable that a permanent set has taken place in the shock mounts and no allowance needs to be considered in aligning the spinner with the cowling. In his column, subtitled "The NACA Counters," Tichenor then took

on a "defender of NACA management," Dr. Edward P. Warner, editor of the rival trade journal Aviation and a long-time member of the NACA's Committee on Aerodynamics and Committee on Materials for Aircraft (Warner had served temporarily in 1920 as Langley laboratory's chief physicist),

who had prepared a response to Tichenor's December 1930 column "Why the NACA?"40 In his editorial response, published in Aviation in January 1931, Warner "skirted the definition of 'scientific research'"41 and by inference, seemed to concede (as Langley chief of aerodynamics Elton W. Miller also

did in an unpublished response he prepared for the NACA Washington Office, which Warner received before writing his own A cowling with well proportioned air inlets and outlets may not need cowl flaps to maintain acceptable engine temperatures.

I suggest you defer the installation of cowl flaps until after a number of test flights have been completed. . . you may not need them. That Oil Inspection Door Many builders make their oil access door much too small and often locate it poorly - directly over the oil dipstick.

Since the dipstick housing is slanted rearward, it is better to locate the oil inspection door somewhat further aft to make the addition of oil less messy and easier. So a nacelle refers to the whole covering of an engine that is outside the plane, typically on the wing.

The cowling would just be the removable part of this cover. As Jan Hudec commented, engines mounted in the nose, as is typical in smaller aircraft, would have a cowling to allow access and cooling to the engine, but technically not a nacelle, since the covering would be part of the fuselage.

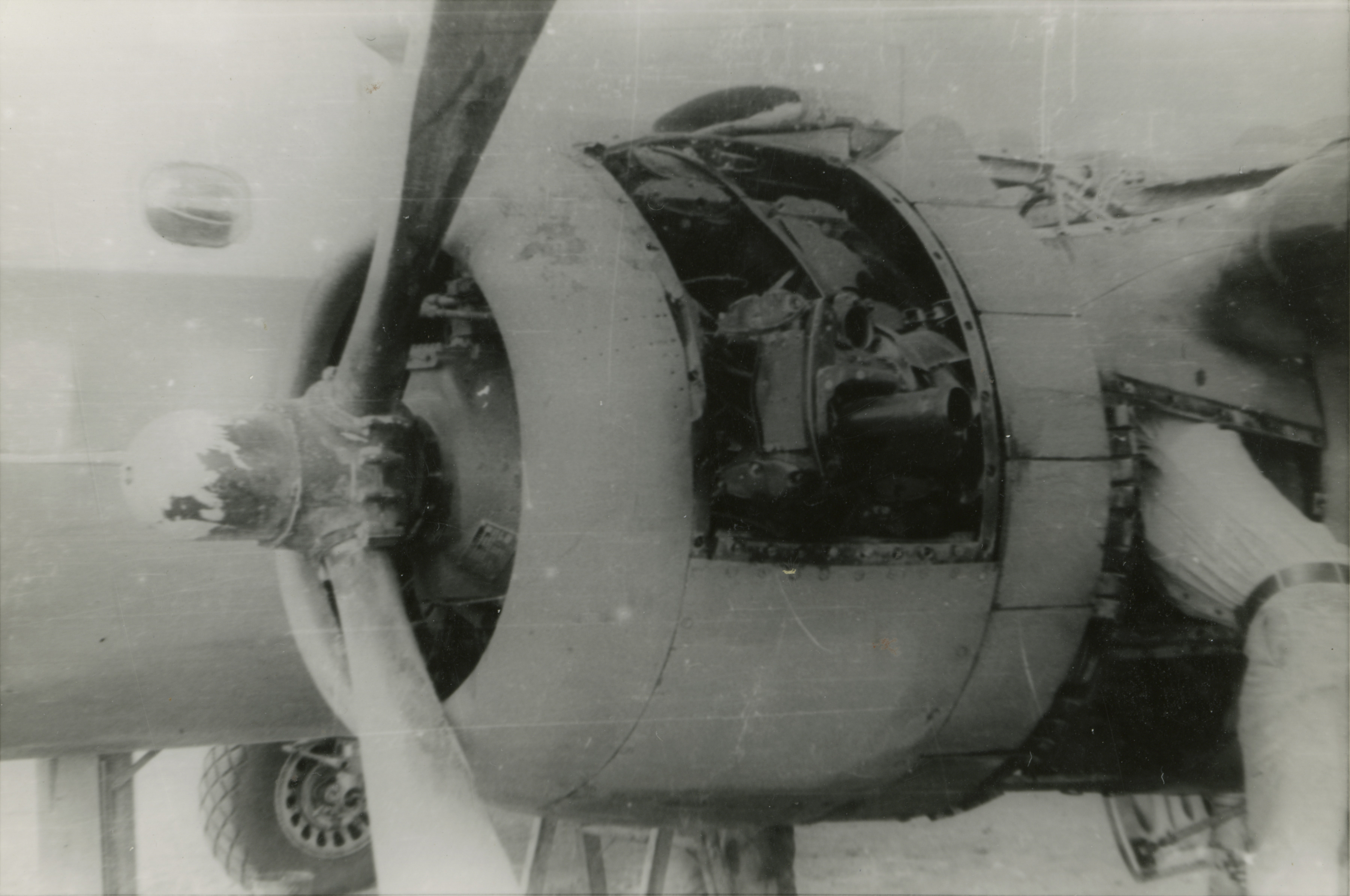

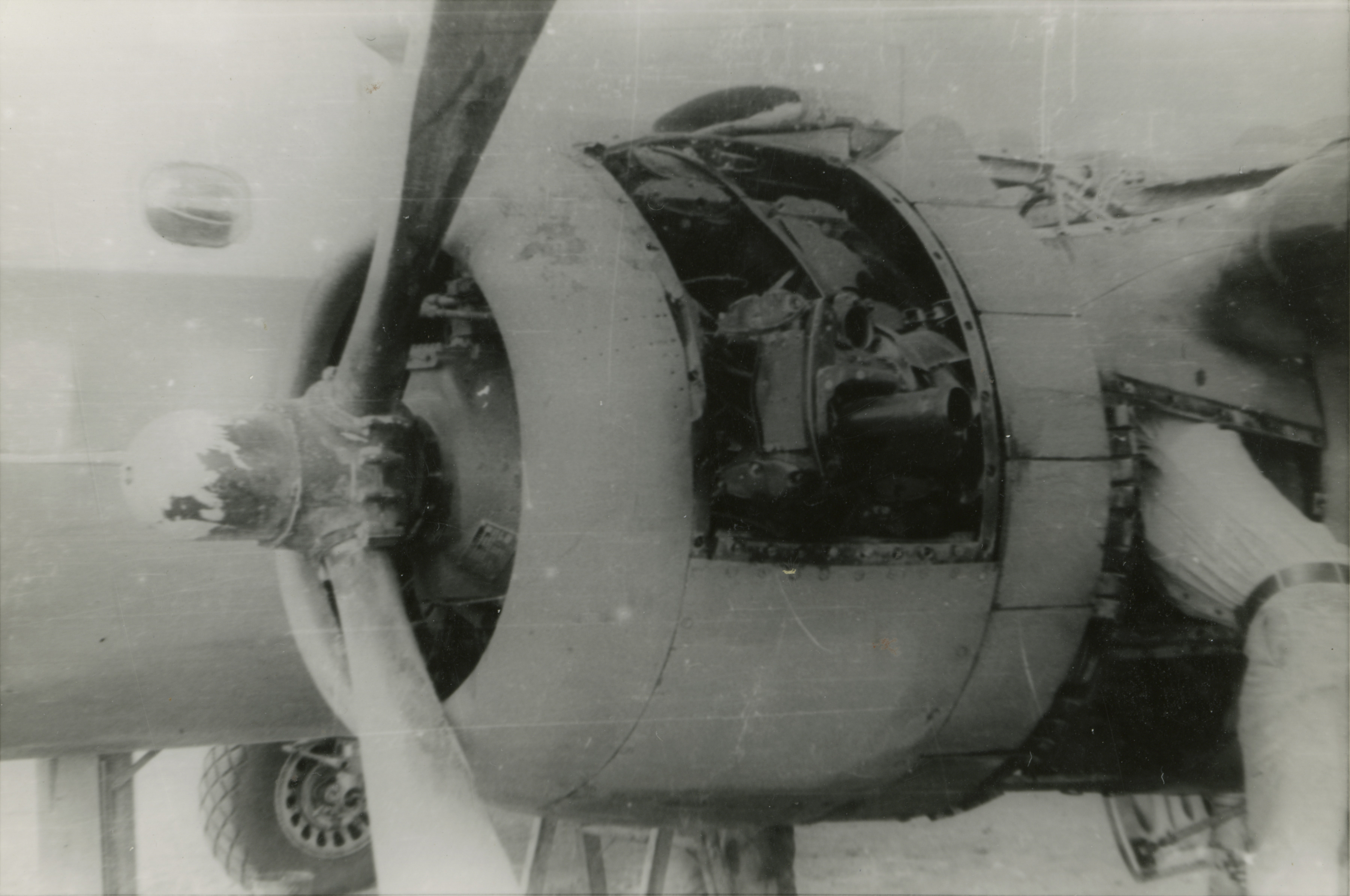

In terms of engineering, there were still a number of bothersome and potentially dangerous unknowns. As evidenced in the question asked of the NACA at the 1926 conference, no one knew for sure how to reduce the engine

drag without degrading cooling. But there were so many of these questions still need to be asked. No one knew with certainty how to shape wings to increase lift or to diminish the effects of turbulence.

No one knew how and when flaps, ailerons, and other control surfaces worked best. No one knew if it was even worthwhile to retract landing gears (according to various pundits, the added weight and complexity of a retractable undercarriage

would not be worth the saving in air resistance). Substantial increases in aerodynamic efficiency might follow on the heels of correct answers to just a few of these technical concerns, but no one knew exactly how,

or even whether to try, to get at them. What Theodorsen believed the NACA needed in order for it to move beyond the impasse now blocking the progress of its experimental cowling program was more attention to the "pencil-and-paper" work that could lead

to a complete mathematical and physical understanding of the basic internal and external aerodynamics of the different cowling On the other hand, if you are a kit builder you have to be sure that the cowling provided will fit your particular installation.

That is, if you plan to use a constant speed instead of a fixed pitch propeller, you might have to modify the cowling you received. Nacelle comes from the French word "nacelle" which is the gondola or wicker basket suspended beneath a balloon.

So, by analogy, many things that are outside the body of an aircraft, like the compartments that house the engines, can be called nacelles. A cowling is the covering of a vehicle's engine even if that engine is not inside a nacelle.

Donald H. Wood, a 1920 graduate in mechanical engineering from Rensselaer Polytechnic Institute who had been working at Langley since 1924, was in charge of the actual operation of the testing, and the first of these modifications

was made while Weick was away on a vacation. When Weick returned to work, it was obvious to him that "the boys were on to something, and from that time on we all worked very hard on the program." 27

Before you can get started on making the mold you must obtain the spinner you intend to use or at least know its outside diameter measurement. A large spinner is quite effective, especially when used with Lycoming installations as its large diameter will help nullify the blunt front end with its bulky starter ring.

A large spinner also minimizes the need for a propeller extension and permits developing a more effective aerodynamic shape up front. Cowling Security The cowling is subjected to two large forces or pressures. It must handle the rush and pressure of the incoming (inlet) air and it must withstand the pressure exerted by the heated exiting air.

These two forces impose considerable pressure from inside the cowling and only the cowling fasteners prevent it from bulging or blowing off. could have backfired. But in historical perspective, a more honest and fully informative approach by the NACA to the importance of its basic activity

seems worth the risk. The cowled engines of American airplanes probably would not have performed any better, but the public context for government R&D may have matured a bit-and in the long run, led to a more informed

public, wiser political decisions, and more logical next steps. Sounds good but cowl flaps complicate the cowl installation. You must remember they will have to be disconnected before you can remove the cowling. On reinstallation, the cowl flap mechanism will again have to be reconnected and tested for operation.

With its winning of the Collier Trophy for 1929, the NACA missed an excellent opportunity to explain to the aviation public, which was growing ever larger and generally more informed during the post-Lindbergh era, what successful applied research done by the government was really all

about. Even if the NACA had provided brilliant explanations, of course, the public might not have cared to listen. But for the general Finding a good method for securing the cowling wire ends is important because to have one of them vibrate out and contact the propeller would be dangerous if not disastrous.

Believe me, it does happen even when you think your wires are too hard to get in. Anyway, you think they couldn't possibly work out. Oh yeah! DESIGNING A COWLING MALE MOLD OR PLUG Before you can make a fiberglass cowling you must make a male mold.

The development of a good accurate mold over which you can form your fiberglass shell is the most difficult part of making a cowling. Of course, laying up a fiberglass shell over a male mold and finishing its external surfaces entails a lot of hours spent sanding, filling and finishing.

Still, that is the most economical way to do it if you only need one cowling. The alternative is to make a second mold, a female mold, from your male mold. Milwaukee, Wisconsin, a subsidiary of United Aircraft and Transport

Corporation. He returned to Langley in less than a year as assistant chief of the LMAL aerodynamics division, a position from which he could work with any of the wind tunnels as well as the flight section.

In this capacity, Weick stayed in touch with the cowling program but it did not monopolize his time and energies as before.62 war-surplus Breguet fourteen biplanes into "Yackey Transports"), he started a job with the U.S.

Navy Bureau of Aeronautics in Washington, D.C., where, within a matter of months, the NACA's director for research, George W. Lewis (1882-1948), personally recruited him for important work to be done at Langley, some 120 miles to the southeast.

(The NACA's Washington office was located in an adjacent wing of the Navy building, thus facilitating close relations between the NACA and the Navy.) Weick arrived at Langley in November 1925 just in time to take over the design and construction

of the new Propeller Research Tunnel, the job Lewis had specifically picked him to do. 17 With the plywood jig in place, it will support the front end of the cowling and automatically align it with the engine.

One more thing must be done. Small wooden spacer blocks may have to be taped to the front face of the plywood jig to establish the proper clearance between the cowling and the propeller spinner. Remember the spinner bulkhead has a 1/2" or 5/8" flange that faces the engine.

The blocks are to provide clearance for the spinner bulkhead flange plus 1/4" clearance. Ultimate success in research is never inevitable, however. Without the help of Theodorsen or someone else with comparable analytical and mathematical talents, the cowling research at Langley might have remained indefinitely

at the point of impasse. Much of the responsibility for misunderstanding the true achievement of the NACA cowling program belongs to the NACA, whose leaders and publicists of the late 1920s and early 1930s, in seeking to

gain respect and additional funding for the honestly meritorious operations (and future wind-tunnel building projects) of their struggling research agency, exaggerated the mysterious wonders of the NACA cowling and continued to stress the scientific character of all NACA research when they should

have been advancing a more utilitarian view of basic research methodology and of technological progress. In doing so, they condoned the miscasting of the cowling as a heroic invention which, in some key respects, represented it as something less than it was.

If you are not ready to install your cowling you may have plenty of time to examine a few homebuilts to see how other builders installed theirs. Study the accompanying photos and you may pick up a few ideas.

The agency that preceded NASA, the National Advisory Committee for Aeronautics (NACA), won its first of five Collier Trophies in 1929, and did so basically for advancing a counterintuitive idea. The idea, which flew in the face

of a conventional wisdom about proper aircraft design, ventured the following: covering up --not leaving open to the air the cylinders of an air-cooled radial engine could not only dramatically reduce aerodynamic drag but actually improve

engine cooling. The immediate product of this startling engineering insight was the NACA's development of a low-drag engine "cowling," the winner of the 1929 Collier Trophy. One would hope that Ames, an accomplished physics professor at (and

later president of) the Johns Hopkins University, understood that the NACA cowling was producing solid, but not fantastic, results and that's it there was no magic in the tin shape. As a member of the NACA Main Committee since

the NACA's establishment in 1915, he certainly should have To be assured of adequate clearance under your cowling in these critical areas, tape 1/2" wood spacers to each spark plug elbow and to any other protrusion that might touch the cowling. Do the same thing to the exhaust pipes where they pass close to

the cowling. Only here use 1" spacers as you will need a minimum of 1" clearance between the stacks and the cowling to prevent its burning or blistering the paint. Perfect the surface contours of the mold by checking the surface with a flexible chalk-coated slat (1/8" x 2" x 24"). Coat the wood slat with colored chalk and then rub it lightly all over the cowl mold surface to

locate the high spots. The high spots will show up as starkly smudged areas. Sand these high spots lightly and continue the chalk and rub process until the entire surface smudges uniformly. The NAA presented the award to the NACA at a brief ceremony on the grounds

of the White House on June 3, 1930, "before a small but distinguished gathering of aeronautical authorities."33 President Herbert Hoover presented the trophy to Dr. Joseph S. Ames, the NACA chairman (1927-1939). Significantly, none of the speakers said anything

Weick and his colleagues remained extremely proud of this contribution for the rest of their lives. In his autobiography, Fred wrote: "This combination, according to some historians, was one of the important advances that enabled airliners to become financially self-supporting, that is, without the need

for government subsidy."57 As such, it fulfilled the NACA's public mandate, put another feather in the cap of the still fledgling government research organization, and demonstrated again, for better reasons than even the original ones, that the NACA's

winning the Collier Trophy in 1929 was well deserved. The most commonly used method for securing the wires is to form a closed loop (or eye) on the end of the wire and fasten it to the cowling with a pan head stainless machine screw.

It will be necessary to install a plate nut behind it. NACA's Washington office announced to the press that aircraft manufacturers could install the NACA's low-drag cowling as an airplane's standard equipment for about $25 and that is the possible annual savings from industry's use

of the invention was in excess of $5 million-more than the total of all NACA appropriations through 1928.29 Next turn your attention to the engine. An aircraft engine is a rather lumpy object having things sticking out here and there and not necessarily where you would prefer to see them.

I have in mind items like the spark plug elbows, the starter ring (Lycomings), exhaust pipes, the carburetor and especially its heat box. These protrusions represent potential problem areas which can influence the shape and design of your cowling.

engine cowling aircraft, james aircraft cowlings, aircraft cowling for sale, james cowl, aircraft cowling design, airplane cowling, sam james cowl, aircraft cowling fasteners

Our company has access to thousands of private planes based around the world, and all of the aircraft we use to arrange private flights operated by FAR Part 135 or 121 (or foreign equivalent) air carriers.

Our company has access to thousands of private planes based around the world, and all of the aircraft we use to arrange private flights operated by FAR Part 135 or 121 (or foreign equivalent) air carriers.